- Turning, milling, drilling, grooving, and threading operations.

- Suitable for steel, stainless steel, cast iron, aluminum, and non-ferrous metals.

- Used across industries like automotive, aerospace, mold & die, oil & gas, and general engineering.

- Compatible with CNC lathes, VMCs, and other precision machines.

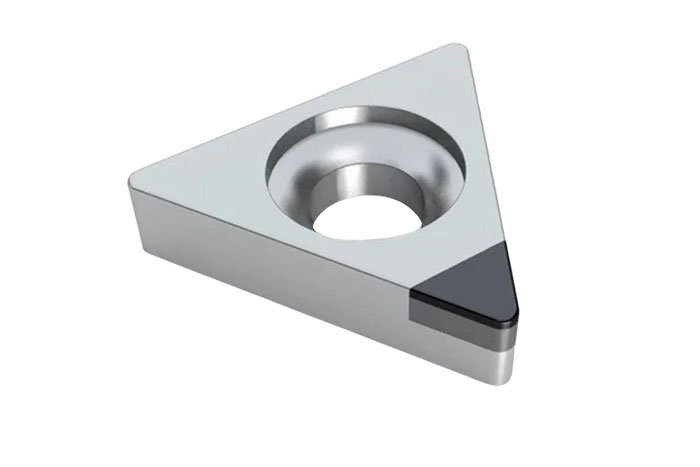

Rostock Inserts

Rostock Inserts

Rostock Inserts are high-precision, industry-grade cutting tools engineered for performance, durability, and efficiency in metal cutting operations. Made from premium tungsten carbide and enhanced with advanced PVD/CVD coatings, these inserts deliver excellent wear resistance, edge stability, and heat resistance. Available in a wide range of geometries and ISO standard sizes, Rostock Inserts are designed to meet the evolving demands of CNC machining and high-speed manufacturing environments. Whether it’s turning, milling, grooving, or threading, Rostock offers both standard and customized solutions for reliable, high-accuracy results.

Key Features

- Manufactured from high-quality tungsten carbide.

- Enhanced with PVD or CVD coatings for longer tool life.

- Sharp cutting edges for excellent surface finish and accuracy.

- Available in various chip breakers, shapes, and ISO grades.

- Designed for roughing and finishing operations.

- Supports high-speed and interrupted cutting.

- Custom insert solutions available for specific machining needs.